In various industries where a clean and oil-free vacuum is a necessity, the Gardner Denver Screw Vacuum Pump S-Series stands tall as a reliable and efficient solution. With its dry and contact-free operation, this pump offers a range of advantages such as eliminating process contamination and minimizing pollution caused by pump operation. Let’s delve deeper into the features, technical specifications, and applications of the Gardner Denver Screw Vacuum Pump S-Series.

Unparalleled Performance and Design

The S-Series screw vacuum pumps from Gardner Denver boast a wide performance range, offering an ultimate vacuum of 29.917 inHgV (0.075 Torr) while maintaining the flexibility to operate at any pressure between maximum vacuum and atmospheric pressure. With capacities of 70 and 212 cfm, these pumps can handle demanding industrial applications with ease.

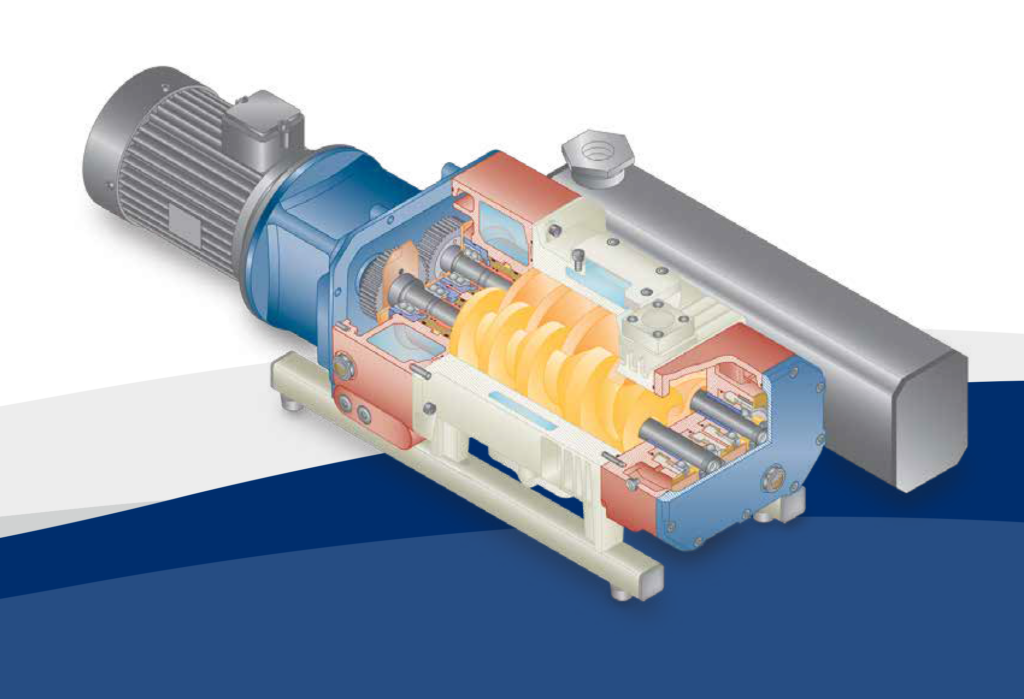

The pump’s robust design ensures durability and reliability. Inside the pump housing, two parallel screw rotors, synchronized by timing gears, rotate in opposite directions. Lubrication is achieved through oil in the gearbox and mechanical seals, while cooling is facilitated by the continuous flow of coolant through the pump housing. This combination of features not only ensures a long service life but also provides high vapor and liquid tolerance, low noise, and low vibration.

Versatile Applications

The Gardner Denver Screw Vacuum Pump S-Series finds its applications across a wide range of industries where clean and oil-free vacuum is required. It excels in general industrial applications such as packaging, drying, and coating, as well as in vacuum furnaces. Moreover, these pumps can be integrated with vacuum boosters to create customized vacuum systems capable of handling high suction capacities.

Technical Excellence

The advantages of the Gardner Denver S-Series screw vacuum pumps are numerous. They operate without the need for lubrication, making them suitable for processes where contamination must be avoided. Additionally, the pumps offer high water vapor tolerance, short evacuation time due to their high suction capacities, low noise levels, and easy serviceability. These features ensure efficient and reliable performance, reducing maintenance time and costs.

Operating Principle

The screw vacuum pump operates using two parallel, screw-shaped rotors—one with a right-hand thread and the other with a left-hand thread. These screws turn in the compression housing without friction, thanks to tight clearances and synchronization via a precision gear. The compression chambers are formed by the shape of the screws and the compression housing. As the screws rotate in opposite directions, gas is transported into the compression chamber, compressed, and discharged through the pressure connection. Cooling is facilitated by a water-cooled outer chamber.

Applications Galore

The Gardner Denver Screw Vacuum Pump S-Series finds its applications in diverse industries. In industrial settings, it assists in cleaning, coating, drying, and dust extraction systems. In the packaging industry, these pumps contribute to central vacuum systems and vacuum packaging of food. Research and development laboratories benefit from their use in various process applications. Moreover, the S-Series pumps are employed in solar technology for tasks like cell lamination and glass plate handling. They are also integral to surface technology and electronics processes such as CVD and PVD processes, as well as vacuum metallurgy.

The Gardner Denver Screw Vacuum Pump S-Series represents the epitome of performance and reliability in industrial vacuum systems. With its dry running and contact-free operation, robust design, and wide range of applications, it provides efficient and clean vacuum solutions. Whether it’s for general industrial purposes or specialized applications, the S-Series pumps deliver outstanding performance, contributing to increased productivity and enhanced operational efficiency across industries. Trust Gardner Denver to be your partner in achieving excellence through innovative and high-quality vacuum solutions. For help with choosing the right screw vacuum pump for your project, please contact a Dearing representative today or request a quote online.