What is Isentropic Efficiency?

Simply stated, isentropic efficiency is a ratio that indicates how the real energy consumption of an air compressor compares to that for an idealized compression process. The value is expressed as a percentage, and a compressor with a higher number is more efficient at converting electrical energy into compressed air potential energy than a compressor with a lower number.

There is no ideal compression, as there are inevitable losses in the real world. For a bare compressor, the power consumed at its shaft (actual work) includes internal losses such as frictional (e.g., created by lubricant film between rotating and static components), inertial (e.g., created by speed changes of reciprocating masses on piston compressors), flow resistance (e.g., pressure losses at intake and outlet ports, including valve losses on reciprocating units) and mass–flow losses (e.g., gas density changes resulting from oil injection heating of rotary screw threads).

For a packaged compressor, the bare compressor losses are combined with driver efficiency (e.g., electric motor efficiency), flow resistance (e.g., pressure losses introduced by oil separation vessels, filters, heat exchangers, pipe works, etc.) and mass-flow losses (e.g., gas density changes resulting from heating effects introduced by protective enclosures).

Isentropic efficiency (IE), which can be calculated and measured independently of compression technology (positive displacement, dynamic, etc.), is not measured directly; rather, it is derived from power consumption, pressure ratio, and delivered capacity. Within the range of pressures typically found in industrial compressed air systems, this measure as it pertains to a specific machine does not change with changes in pressure. In order for an isentropic efficiency number to be meaningful, it is essential that both the ideal and actual work values be calculated or measured at the same operating pressure.

Fixed speed compressors have one isentropic efficiency number. Variable speed compressors have their isentropic efficiency determined as a weighted average of efficiencies at various, standardized load levels. This reflects the performance of compressors running between 40% and 100% of their capacity. If the demand is in a smaller range than that, it may be prudent to check the specific power curve on the data sheets and compare compressors operating within that range at the anticipated pressure rating.

SIMPLY STATED

- Isentropic Efficiency (IE) compares the actual performance of a device to the performance under idealized circumstances for the same inlet and exit states

- In the simplest form, we are measuring how efficiently the compressor is converting electrical energy into compressed air potential energy

- It is measured as a percent and the higher the %, the more efficient the compressor.

- The better the compressor design is at reducing the real world losses, the higher the IE will be and the lower its specific power will be.

- Isentropic Efficiency makes it far easier to compare compressors with different full-load operating pressures

IE = Energy (kW) for the Ideal Compression Process /Actual Energy (kW) Consumed

- The key is that IE incorporates discharge pressure into the calculation such that the IE rating of compressors with varying discharge pressures are comparable

- The IE metric makes the comparison apples-to-apples on full-load operating pressure, which is critical

WHAT IS SPECIFIC POWER?

Specific Power, sometimes called specific energy, is an absolute energy-use metric that provides energy consumption per unit of delivered capacity. It is the ratio of the actual work to the actual volume flow delivered by the gas compressor.

Specific power is a dimensioned ratio and must be linked to the original test-pressure in order to be comparable. Whereas isentropic efficiency provides annituitive means of comparing performance, with higher numbers representing more efficient machines, specific power is less intuitive. With specific power, a lower number, demonstrating less energy used to compress a given volume of air, represents the more efficient machine, all other things being equal. Specific power is much more useful for calculating actual compressor power costs when the flow and operating time are known.

TOTAL COST OF OWNERSHIP OF AN AIR COMPRESSOR

The better the compressor design is at reducing the real world losses, the higher the Isentropic Efficiency will be and the lower its Specific Power will be.

Why hasn’t isentropic efficiency been used before by manufacturers?

Specific Power has been the industry standard metric for many years. It provides the customer with information that can be used to estimate energy consumption over time, but it does not provide an easy way to compare two different machines. A specific power is a specific metric that is dependent on discharge pressure. Unless two machines have identical discharge pressure, it’s not possible to accurately compare them.

Using efficiency as a measure of a machine’s effectiveness, allows the customer to make a more direct comparison of two or more machines irrespective of the exact rated pressure.

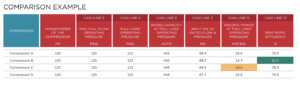

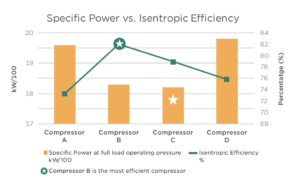

- The table above shows all units can deliver full flow at 125 PSIG

- However, all the units are not rated at the same pressure (CAGI Line 4)

- Thus, the flows, input kWs and Specific Powers are not calculated at the same pressure

- Just based on the CAGI Line 12 Specific Power numbers, Compressor C looks most efficient

- With Isentropic Efficiency, the different rated pressures have been accounted for and Compressor B is most efficient

How are efficiency and energy use metrics practically applied?

Ideally, use of both numbers, isentropic efficiency and specific power, will allow individuals to make the best choice for their specific application and situation. When evaluating compressor systems, the use of isentropic efficiency provides the customer with additional valuable information to evaluate the suitability of products for the customer’s specific application. By itself, efficiency does not provide a means to make a selection because it needs to be quoted with capacity and rated pressure. For two compressors that are rated at similar capacities and rated pressures though, using efficiency values does provide a direct means of comparison.